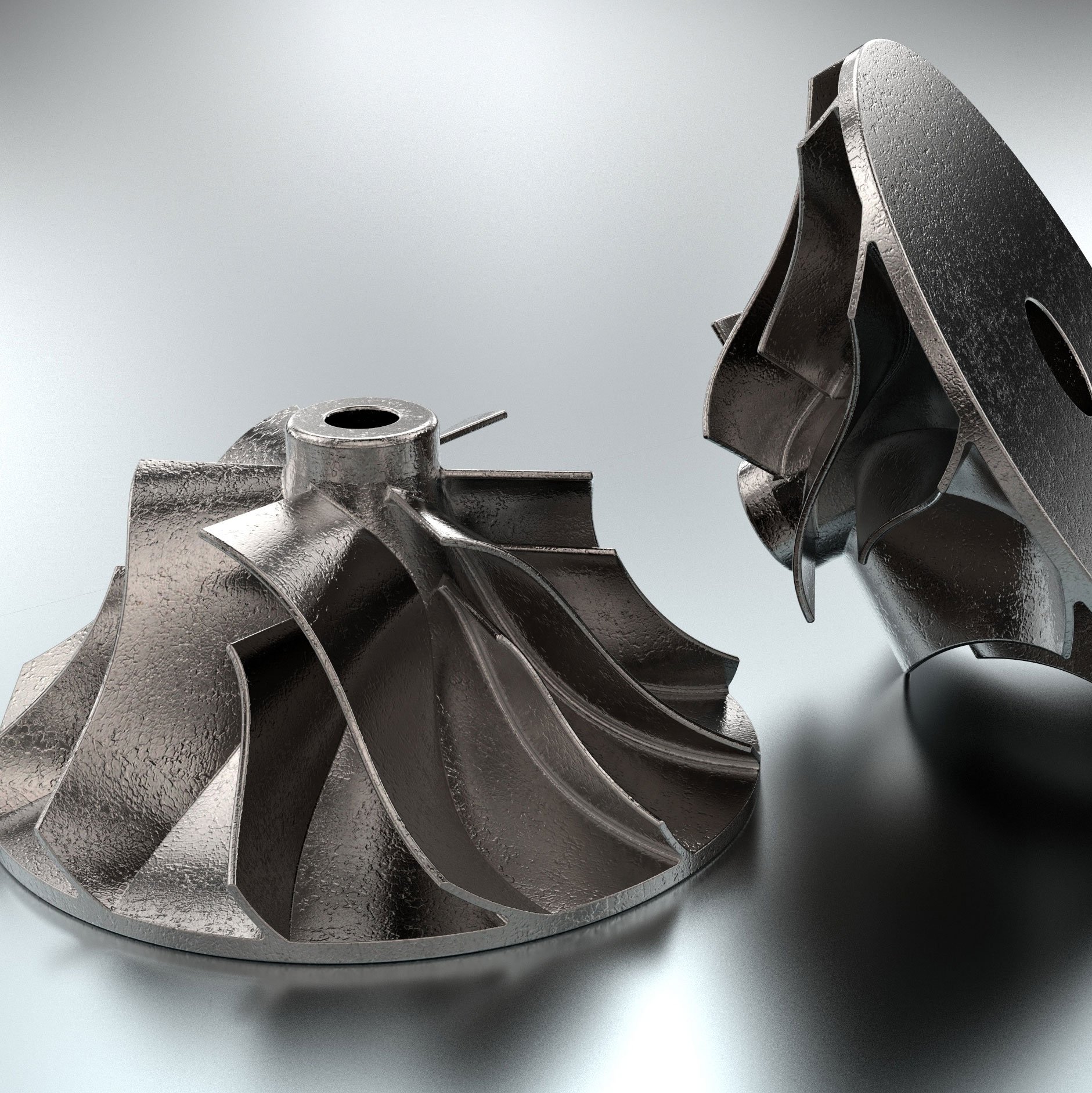

Enabling Mission Critical Parts that Meet Rigorous Quality Standards

The Defense industry is committed to transforming the conventional supply chain with distributed manufacturing in order to enhance warfighter innovation and improve battlefield readiness. To achieve success, government entities, civil protection agencies and military suppliers are implementing metal additive manufacturing technologies to produce parts on-demand for applications that are near the battlefield. This includes MRO or spare part replacements, customized production needs, emergency relief applications and other mission-critical objectives, including:

- Research & Development

- Prototyping and Concept Validation

- Bridge Production

- Jigs, Fixtures, and Custom Part Development

- Repair

The challenge is that metal additive manufacturing processes and materials are not standardized for critical components and applications.

Sigma Additive Solutions’ PrintRite3D solution completes the digital thread and enables engineers, researchers and scientists to print qualified metal parts that meet the strictest guidelines and standards, allowing you to manufacture with confidence.

PrintRite3D® is an interactive in-process quality assurance system that combines inspection, feedback, data collection, and critical analysis. By actively monitoring the quality process and providing real-time defect detection, PrintRite3D ensures high-quality output that meets regulatory and certification requirements. The solution is based on a decade of intensive research and collaboration with OEM providers and research institutions and is designed to enable end-users and service providers to manufacture parts with confidence. PrintRite3D is compatible with major metal additive printer manufacturers.

The Department of Defense as well as support agencies and commercial suppliers requires a tool that maximizes the potential of metal additive manufacturing and mitigates risks. OEMs and suppliers are actively defining QA standards in-house for metal AM and those who are first to accomplish this will gain a significant competitive advantage in the market. Sigma Additive Solutions can assist your R&D, prototyping, and production departments to improve part performance and develop reliable standards that will help streamline your entire manufacturing efficiency.

Benefits of PrintRite3D:

- In-Process Quality Assurance that immediately detects part anomalies and potential defects.

- Reduces your post-production testing time and costs.

- Provides part transparency with non-destructive testing.

- Enables secure transfer mechanism for digital files for IP protection and true build portability.

- Ensures part reliability that meets predetermined standards and qualifications.

- Facilitates a closed-loop system for build planning, monitoring and feedback control.

- Advances modeling and simulation by integrating processes and raw material data.